Vaqua Wet Blast Systems: Triple Play

3 Operations Available:

Wet Blast,

Rinse,

Blow-off

3 Styles to Choose From:

Manual,

Automatic,

Robotic

3 Part System:

Cabinet,

Vaqua Slurry Pump,

Recirculating Rinse Tank

Combine Three Operations Into One

The Vaqua Wet Blast system is the ideal solution for surface preparation, cosmetic finishing, low-impact cleaning applications, and degreasing. In one operation:

- Blast without embedding media particles

- Pre-rinse blasted components prior to a final rinse

- Blow-off parts before they exit the blast system

See How it Works

Vaqua’s Blasting Action

Unlike dry blasting techniques that rely on impact to do the work, Guyson’s Vaqua Wet Blast is engineered to produce a powerful scrubbing action that removes surface deposits, contaminants, scale or burrs. This scrubbing action can produce polishing effects that cannot be achieved through the use of ordinary line-of-sight dry blast surface treatments.

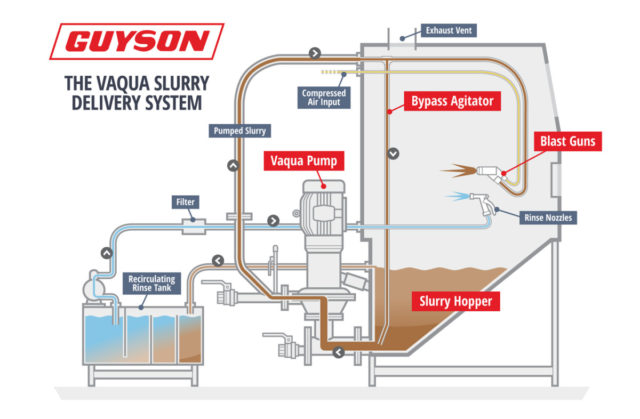

Vaqua Slurry Pump Delivery System

Slurry is pumped by Guyson’s proprietary delivery pump to the Vaqua’s boron carbon nozzles. Mounted on the outside of the blast enclosure for easy maintenance, the slurry pump is powered by motors ranging from 2hp to 20, depending on the application and number of blast nozzles required.

Features

Dust-free Blasting

The Vaqua Wet Blast is a dustless, self-contained, closed-loop system. It eliminates harmful dust and prevents static build-up when descaling titanium parts.

Blast Cabinet: Built to Last:

Everything about Guyson’s cabinets, from the hopper to structures exposed to slurry are reinforced to withstand even the toughest use.

No Sloppy Media Removal

Blast media can be changed without having to remove the water in the system. A cyclonic media separator can be connected to the slurry delivery system.

Optional Recirculating Rinse System

The baffled stainless steel recirculating rinse tank is interconnected with the slurry hopper for a closed loop system. It can be fitted with a skimmer to remove floating oil or grease.

Optional Features

- Rotary Table

- Rotary Spindle

- Enhanced Media Delivery

- Pass-through Conveyor

- Spinner-hanger and Monorail Systems Available

We stand behind every machine we make

Whether you need spare parts, blast media, maintenance information or answers to technical questions, Guyson’s Customer Service Team is ready to assist you.