Firearms Finishing

Gun Parts Prep for Coating

For the past 60 years, Guyson has served as a benchmark for gun manufacturers and metal-coating companies

Our machines get more work done. The cost per part is the lowest in the industry while our ability to increase production is the highest in the industry.

Guyson machines have the highest uptime of any blast machine on the market today.

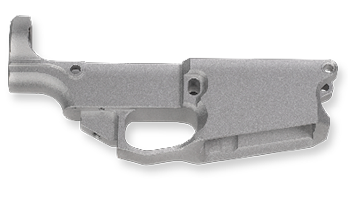

Grit blasting is a popular and cost-effective method for preparation before coating — whether you’re applying Cerakote®, parkerizing, black nitride, Ion Bond-DLC, black oxide, or MIL-SPEC Type III anodizing (per A-8625). Guyson firearm blast machines have proven they can meet these stringent requirements for a perfect finish every time.

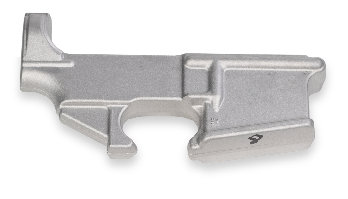

Guyson has developed many custom solutions to blasting pistol frames, slides, bolt carriers, trigger guards, cylinders, barrels, yolks, silencer components, and even upper and lower receivers.

Get the Quality You Want and the Consistent Finish You Need for Your Final Product

Get more work done

The Guyson 900 Blast Gun, combined with our Media delivery system, can deliver as much as 10 times the amount of media in the same period of time as our competitor. This

means you can finish more guns with one cabinet than you could with multiple cabinets from our competitors using the same amount of energy!

Cleaner, more efficient reclaim system

Our reclaim systems will leave your shop cleaner and your products brighter. With more pressure going into the gun, rather than into your shop, you will enjoy a cleaner shop environment.

Ramp up faster

Guyson can provide you one of our standard industrial blasting machine in a timely manner. Start your saving sooner, and clean up your blasting environment.

Six Decades of Working with the Firearms Industry for Low and Large Scale Production of Gun Parts and Accessories

Wet Blast Machines

Manual Cabinets

Robotic Systems

We specialize in Wheelblast, dry blast and wet blast machines, ranging from manual blast cabinets like the Model 8, to fully automated systems like the Guyson RXS family and custom robotic systems.