At Guyson we offer you blast finishing solutions for a vast range of surface treatment applications. We can help you to select the most appropriate system for your particular needs – whether it is a simple manual blast cabinet or a customized machine. For use by an operator or automated and help choosing the right blast media to achieve the results you wish. Just read this sample list of applications to see some examples.

METALS

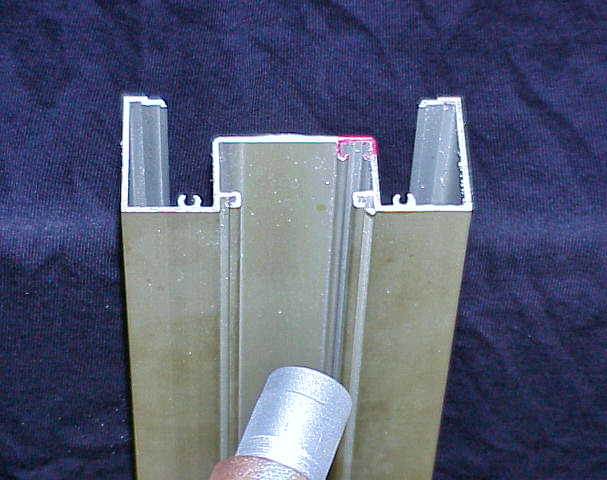

• Removal of light burrs from machined parts.

• Surface preparation or ‘keying’ to improve coating or paint adhesion.

• Mould, die and tool cleaning without damage to sensitive surfaces.

• Peening to improve fatigue life and corrosion

Huge selection of blast media options at Guyson Corporation.

• Deburr machined parts – even sensitive alloys and fragile materials – without affecting critical surface areas. Guyson non-abrasive blast techniques can eliminate labor-intensive and inconsistent hand deburring operations. Burrs can be quickly and cleanly removed from intricate contours and otherwise inaccessible areas.

• Descale and clean a tremendous variety of metal to prepare for subsequent operations. Remove tough mill scale, oxidation, heat-treat scale, discoloration, weld scale and other surface deposits that interfere with painting, coating, thermal spraying, drawing, etc.

• Deflash die-cast metal, molded plastic or encapsulated electronic components quickly and thoroughly. Flash can be removed by precise selective blast treatment, or at the same time as a clean surface or an overall cosmetic finish is produced.

• Strip paint, lacquer and other coatings with speed and precision – with no hazardous chemical handling and disposal headaches. Layers can often be stripped without removing undercoat or affecting sensitive substrates, such as aluminum alloys and composite materials. If desired, surface preparation can be combined with coating removal purposes.

• Clean dry residues, rust, corrosion, tarnish, combustion deposits and other surface contaminants quickly and efficiently, even from complicated shapes and delicate materials, without dimensional change. Cut cleaning costs and improve results.

• Etch surfaces to achieve the texture you require, whether as a preparation for coating, bonding, painting, plating, etc., or as a final esthetically pleasing finish. The degree of roughness and areas to be selectively etched can be precisely controlled.

• Shot peen ferrous and non-ferrous alloy components to upgrade their performance under critical conditions. Guyson’s state-of-the-art controls engineering and well developed portfolio of automated systems enable peening to precise intensity with uniform, repeatable coverage.