Why use a Robot for your blast application? A more appropriate question might be, why not?

Does your application require….

Consistency?

Accuracy?

Flexibility?

Do you need to accommodate….

EHS concerns?

Automatic part loading?

Stringent specifications?

At Guyson, we specialize in robotic blast systems for every application, including yours. Have you consider switching to robotics, let’s look at the many ways Guyson can help. The transition can be made easier when you ask Guyson to participate in the machine selection process, blast application development, floor plan arrangement and final design,Followed by taking advantage of our service and support after the sale.

We build custom and semi-custom automated Robotic systems in three broad configurations.

Robotic part handling with an automatic grit blaster or shot peener.

Your parts are delivered to the material handling Robot using your preferred method. If you need help, we can provide a custom part delivery system, simple conveyor or tie into your existing means of moving parts.

Parts are manually loaded into a robotic blast machine.Standard automatic blast machines can have a robot inside, holding one or more blast nozzles, providing consistent blasting as parts pass by.

We also provide pick and place robotic machines.With one such design, the Robot reaches outside the cabinet to grab parts manually loaded into a rack or tray. The parts can also be loaded on trays that are placed on an actuator delivering parts into the cabinet where the robot can pick and place your part.

The parts can also be loaded on trays that are placed on an actuator delivering parts into the cabinet where the robot can pick and place your part.

When full automation is beneficial to your process, Guyson can provide a fully automated robotic blasting and part handling cell. We can work with you to design a part delivery system that fits your needs. Those parts are picked by a part handling robot, delivering parts into the blast cabinet. The parts can be automatically placed in a gripper and blasted by the internal robot.

Does changing to one of these Robotic blasting systems sound like a difficult process; Not when you involve the Guyson engineering team.

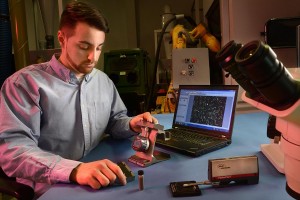

- Our Engineering laboratory includes a robotic test blast machine, including dry and wet blasting. We can simulate your potential new process in our facility.

- For complex applications robotic simulations can be provided to further prove out the part handling process.

- Blast pattern simulations can show specific blast paths to study coverage and cycle times.

- Design reviews on site or over the internet are often used to show previous similar designs as well as reviewing preliminary designs and floor plan arrangements.

Are you concerned with startup of your new Guyson robotic blast cell at your facility? Don’t be, Guyson can help.

- The Guyson field service team comes to your facility to oversee installation and startup your system.

- Robotic and controls engineers are also part of the new start up providing expert support.

- While on site, our service and engineering teams can provide training tailored to fit your specific needs.

- Factory direct support is here for you, after the sale. With higher levels of service available for purchase, Guyson can accommodate your needs.

- MyGuyson offers 24/7 access to pertinent information related to your system.

Guyson is committed to making your transition to Robotics smooth. From machine selection to service and support, Guyson is your team.

Now, are you ready to make the switch to robotics, Guyson robotics?