Wet blasting equipment is sometimes described as a “closed loop system,” but what does that mean in terms of practical operation and maintenance? This topic is worth some further discussion to clarify the picture.

As diagrammed in a previous post to this blog, our wet blast systems are self-contained and do not have a constant discharge to waste. The slurry solution is recirculated within the system until you decide it is time to replace it.

When discharge is required, a cyclonic media separator is connected to the slurry delivery system between the pump and the wet-blast guns.

When discharge is required, a cyclonic media separator is connected to the slurry delivery system between the pump and the wet-blast guns.

The media separator, occasionally referred to as a hydrocyclone, is a centrifugal-type separator that extracts the media particles from the water portion of the slurry. The water and media mixture is pumped into the media separator, where, by the design of the internal body and cone of the separator, the slurry solution is forced into a swirling action, creating a vortex.

The heavy media particles are forced to the outside of the vortex and directed down the cone to a holding tank. In the center of the vortex is clear water, which flows out the top of the separator and is returned to the wet blast cabinet.

When all the media has been extracted from the liquid, the water portion of the slurry can be drained from the cabinet, and the separated media can be discharged from the holding tank. Then a fresh charge of water, media and other compounds can be added directly to the slurry hopper.

Mini Cyclones

In automated wet blast systems, a scaled-down version of the media separator can be used to provide media-free solution for pre-rinsing of the blasted components prior to either a final rinse or blow-off before the parts exit the blast system.

The polyurethane Mini Cyclone is usually installed on the roof of the wet blast enclosure. While the wet blast system is in operation, a portion of the slurry is pumped to the Mini Cyclone, where the heavy media particles are centrifugally separated from the water and directed back to the slurry hopper for reuse. The clean water is directed to a rinse manifold in the pre-rinse zone of the wet blast system.

Recirculating Rinse

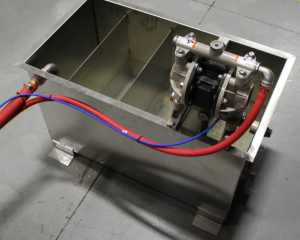

The closed loop wet blast system can be further enhanced by the addition of a recirculating rinse circuit. For this optional feature, a baffled settling tank is interconnected with the wet blast cabinet slurry hopper. The interconnecting point in the hopper is at the very top level of the slurry, in an area of minimal agitation. The topmost level of the slurry will only contain a small amount of fine broken-down media particles suspended in it. The baffled settling tank is designed to create a weir- like path for the water, slowing down the flow to allow the solid particles to settle to the bottom.

The closed loop wet blast system can be further enhanced by the addition of a recirculating rinse circuit. For this optional feature, a baffled settling tank is interconnected with the wet blast cabinet slurry hopper. The interconnecting point in the hopper is at the very top level of the slurry, in an area of minimal agitation. The topmost level of the slurry will only contain a small amount of fine broken-down media particles suspended in it. The baffled settling tank is designed to create a weir- like path for the water, slowing down the flow to allow the solid particles to settle to the bottom.

Fitted to the clean end of the baffled settling tank is a rinse pump. The pump draws water from the tank and sends it to the rinse zone in an automated system or to a hand spray nozzle in a manually operated system. Whenever rinse water is released into the blast cabinet, it creates an overflow condition of the slurry hopper, so an equal amount of water drains back to the settling tank, thus forming a closed loop system.

Additional features can be added to the recirculating rinse system such as in-line filters, oil skimmers and immersion heaters – but the workings and advantages of those options will be the subject of a future post to this blog.