The Guyson AR Mini is an affordable blast finishing machine that is the perfect prep for anodizing, Cerakote or a cosmetic finish. The 201T AR Mini is the ideal machine for small to medium firearms manufacturers, coating shops, or any company in need of a smaller footprint high production machine.

- Are you having trouble increasing production levels, and reaching sales projections?

- Could you sell more guns if you had better turn around in the gun finishing department?

- Is outsourcing too expensive to prep your guns for anodized and Cerakote® finish?

Guyson HAS the answer!

We’ve created an affordable blast cabinet specifically for the Small Firearms Shop.

- Increase productivity. Increase your prep for coating volume while reducing cost per piece.

- Airless wheel blast machine designed to run on single phase power.

- Created for small scale shops.

- We’ve added custom tools that specifically enhance quality and production of your product.

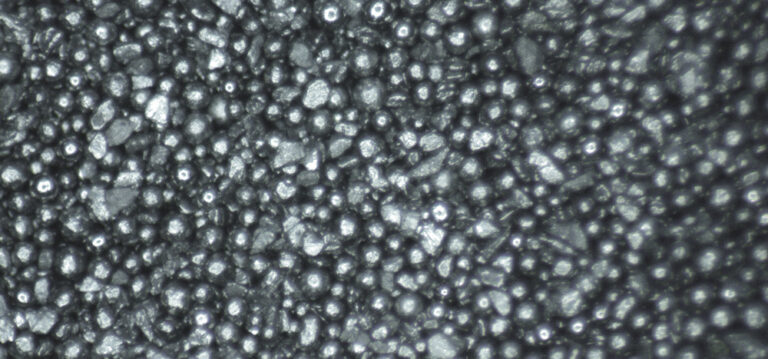

Special Blast Media Specifically Designed for Guyson Wheel Blast Cabinets

The AR-Mini uses the Guyson Firearms blended media to obtain precise and repeatable results. Don’t worry about a clogged blast gun with this machine.

Blast Chamber

The blast chamber is fabricated from heavy rigid steel plate and fully protected internally with abrasion resistant neoprene. Easy access to the blast chamber and worktable. The machine will not blast until the doors are closed. The AR-Mini requires no pit or special foundation for installation.

Sattelite Tables

The worktable has 3 embedded satellite tables constructed of steel and acetal.

Bucket Elevator & Storage Hopper

The bucket elevator carries abrasive to a storage hopper above the blast chamber. The storage hopper holds enough media to keep up with the flow through the blast wheel. Dust is carried out of the elevator into the dust collector.

Waste Tray and Airwash

The waste tray and airwash are standard equipment. Contaminated media and air are pulled through the waste tray and airwash. Larger contaminants are caught in the waste tray screen. Dust is pulled through the airwash and waste tray box into the dust collector, leaving only clean media to go through the system.

Blastwheel Assembly

The 8 inch blast wheel diameter assembly is designed for heavy duty blasting applications. Coupled with a media throttling valve, the blast stream can be easily regulated and targeted for the most efficient blasting life cycle. Blast stream can be easily targeted to ensure the most efficient coverage of the work pieces.

The AR Mini Wheel Blast machine is the ideal machine for lower volume production machine shops, firearms manufacturers or any company in need of a smaller footprint machine.