We Will be Attending the Shot Show in Las Vegas – January 22-26

Sign up for our email list and get a Free Guyson T-shirt or Hat – CLICK HERE

Guyson’s versatility is widely renowned in the Firearms industry. Grit blasting is a popular and cost effective prep-for-coat process, whether it be Cerakote, Black Oxide, or even Anodizing. Guyson has developed many solutions for blasting pistol frames, slides, carriers, trigger guards, cylinders, barrels, yolks, silencer components, and even upper and lower receivers. Guyson has a high degree of success utilizing Robotics and standard automatic blast cabinets for:

Guyson specializes in air blast and wet blast machines, ranging from manual blast cabinets like the Model 8, to fully automated systems like the Guyson RXS family, and custom robotic systems.

Guyson spans 6 decades of working with the firearms industry for low and large scale production of gun parts and accessories!

Get the quality you want and the consistent finish you need for your final product.

201T AR-MINI

AFFORDABLE WHEEL BLAST SYSTEM FOR THE FIREARMS INDUSTRY

Introducing the New 201T AR Mini! This new machine will Increase productivity for your prep-for-coating process. It comes with three satellite tables to guarantee consistent full blast coverage. The “Mini” was designed specifically for the small to medium size firearms manufacturing or coating facilities

The AR-Mini is available with a tumble basket for small parts or a power door as optional features.

401T AR-MAX

Blast Finishing for the Firearms Industry

The AR Max has three custom satellite tables for holding parts and can blast up to 400 parts per hour, depending on your component size. Every part will get full blast coverage during the cycle time. When compared to a manual blast cabinet, the AR-MAX can reduce a process of several minutes down to 10 seconds per component.

The AR-MAX will increase your production levels, shorten turn around time, and will quickly pay for itself.

Get more work done

The Guyson 900 Blast Gun, combined with our pressure system, can pass as much as 10 times the amount of media in the same period of time as our competitor. This means you can finish more guns with one cabinet than you could with multiple cabinets from our competitors, using the same amount of energy!

Cleaner, more efficient reclaim system

With more pressure going into the gun, rather than into your shop, you will enjoy a cleaner shop environment using our reclaim systems.

Ramp up faster

Guyson can provide one of our standard industrial blast machines in a timely manner. Start your savings sooner, and clean up your blasting environment.

Wet Blast: A Cleaner Firearm Production Process

In the production of military and law enforcement firearms, particularly in the processing of parts for service handguns, adequately finishing the slide of the pistol is a common and frustrating challenge. The component’s configuration presents numerous nooks, crannies and hard-to-reach angles that obstruct a sufficient post-machining polishing process on the shop floor. More often than not, sharp burrs are left behind that expose employees to cuts and scratches when handling these delicate components.

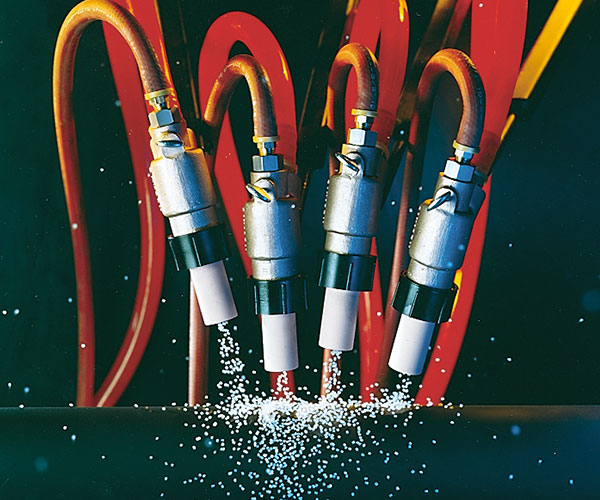

A GUYSON Wet Blast System can blast, rinse and dry these parts using multiple chambers to meet and exceed process requirements. Because the slurry solution gives complete coverage, it can clean and deburr in one step. Also, if the pressure is reduced in the blast chamber, Guyson WBS systems can duplicate a secondary lapping process that leaves an ultra-smooth and cosmetically superior finish.

Benefits for the firearms manufacturing industry

- Near or complete elimination of embedded abrasive media and related voids in the slide reduces injuries in the manufacturing process.

- Ability to etch, rinse and dry surfaces in a non-chemical, water-based, closed-loop system in one integrated, multiple-step work cell — right on the production floor.

- Dust-free, wet-slurry process allows for location of work cell in close proximity to sensitive production areas and increases workflow in manufacturing environments.

- Less production floor space needed due to the elimination of dust collectors.

- High percentage of water in the slurry dissipates heat.

- Improved controls over wet blasting and the immediate lapping of the surface with the same media leads to greater reduction in component Ra values.

- Precise and repeatable delivery of Wet Blasting slurry gets into previously inaccessible places, for a uniform finish.

- Stringent manufacturing standards and low maintenance.

- Easy operational requirements of systems speed ROI and reduce TCO.

We stand behind every machine we make

Whether you need spare parts, blast media, maintenance information or answers to technical questions, Guyson’s Customer Service Team is ready to assist you.