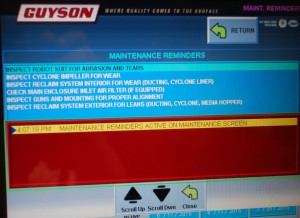

Many customers want the control system to help them keep up with maintenance by providing a reminder and simple instructions. The interval of most preventive inspections is based on elapsed calendar days, blast cycles or blasting hours, and Guyson automated or robotic blast systems can be configured to track scheduled maintenance and alert you when an activity is due, as well as record and time stamp when and by whom scheduled maintenance was performed. Such control system features are not merely a convenience, since timely attention to required machine maintenance is necessary to ensure the integrity of your surface treatment process.

Many customers want the control system to help them keep up with maintenance by providing a reminder and simple instructions. The interval of most preventive inspections is based on elapsed calendar days, blast cycles or blasting hours, and Guyson automated or robotic blast systems can be configured to track scheduled maintenance and alert you when an activity is due, as well as record and time stamp when and by whom scheduled maintenance was performed. Such control system features are not merely a convenience, since timely attention to required machine maintenance is necessary to ensure the integrity of your surface treatment process.

Remote Monitoring

With increasing frequency, Guyson automated and robotic blasting systems are being provided with a built-in ethernet connection to the owner’s internal network. This enables engineering or management resource people elsewhere in or outside the facility to interact with the control system, review and download production or process data, perform diagnostics or upload new part processing programs without interrupting operation of the blasting or peening system.

When a secure internet connection is provided, engineering resources at Guyson can access the control system to remotely monitor machine performance, diagnose hardware or software problems or upload files generated by off-line programming tools.