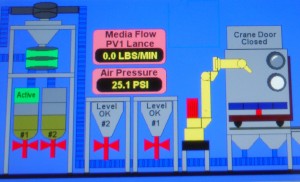

Electronic sensor technology can be applied to make machines easier to use, but also to alert you to any conditions that could compromise the integrity of your process and cause surface defects. Automated sensing of blast parameters such as blast pressure, media level, media flow, reclaim air flow or even a full dust drum can report the status and out-of-limit fault conditions at the HMI, with prompts for corrective action.

Electronic sensor technology can be applied to make machines easier to use, but also to alert you to any conditions that could compromise the integrity of your process and cause surface defects. Automated sensing of blast parameters such as blast pressure, media level, media flow, reclaim air flow or even a full dust drum can report the status and out-of-limit fault conditions at the HMI, with prompts for corrective action.

Closed-loop control of key parameters can be set up to initiate automatic adjustment or self-correction, including the addition of media. A smarter machine safeguards your process and saves you people-time and money.

Motion Control

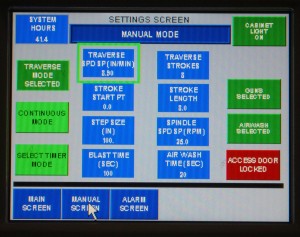

Beyond synchronizing the activity of actuators, valves and switches to open doors and  turn devices on or off at the right time, the PAC supervises the selection, verification and execution of motion programs in the automated system. The design of nozzle or component motion systems with encoders enables precise control of automated processing, with pre-programmed routines for all parts to be processed in the automated blast system stored and recalled by the PAC.

turn devices on or off at the right time, the PAC supervises the selection, verification and execution of motion programs in the automated system. The design of nozzle or component motion systems with encoders enables precise control of automated processing, with pre-programmed routines for all parts to be processed in the automated blast system stored and recalled by the PAC.

In robotic systems, all functions of the blast system are typically assigned to the PAC, except for auxiliary axes of robot motion, with continuous communication between the PAC and robot controller.

Data Acquisition

Digital sensing and ethernet cabling, in combination with a panel PC or server for computing power, enables moment-to-moment capture and recording of process data for analysis and documentation purposes. Log files for monitored parameters can then be accumulated and saved for future reference, usually in an Excel spreadsheet associated with the run cycle. Guyson designs and integrates SCADA and data logging systems based on the requirements of the individual customer, not a pre-configured software package.

For aerospace shot peening and other systems with data logging, Guyson designs a more powerful PC-connected HMI based on robust platforms, such as Rockwell FactoryTalk®, WonderWare®, GE ProficyTM, Siemens SIMATIC WinCC or Mitsibishi GX Developer.